What are the things you must look for in a PCB manufacturer?

After you finish the PCB layout, the next step for first-time designers will be to find a PCB manufacturer. It is the same in most services, and a range of quality results will depend on the design requirements and budget. PCB production has different manufacturing sites that help to save money. However, design stages need more cohesiveness. Some contract manufacturers are well-experienced and capable compared to others. It will pay more to know better the benefits they offer.

Start with services

Only some PCB manufacturers give you the same capabilities or capacity. Differences in market positions, personal expertise, and equipment depend on location. Manufacturers must furnish the core services: pcb assembly, fabrication, and design. The additional support services can change the need for different contractors. The designers will look for some or follow the manufacturing services.

Component procurement

Looking at and choosing the right components to use on your circuit board can be a severe drain on available engineering resources. They are more than looking for the best part at the lowest cost; supply chain disruptions have a complicated calculus for procurement. They have a sourcing department with access to networks of distributors and vendors that find the best components. The staff will stay updated on product life cycles to get obsolete component assemblies.

Prototyping

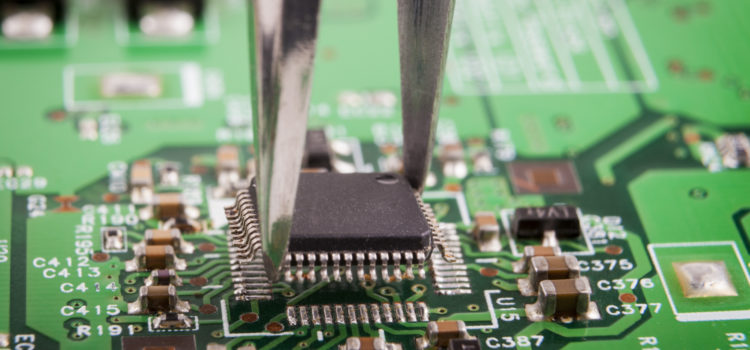

PCB prototyping is a specific type of PCB manufacturing, but the result will have a different goal. General manufacturing is for products ready for market. These boards have extensive research and development into the costs and assembly. It will lessen the per-board expenses in high-volume lots. Prototyping is concerned with testability and development of the board. The processes produce a circuit board with different considerations to increase their effectiveness. Having the difference requires an experienced CM to prototype printed circuit boards.

Layout

When the schematic is more or less finalized, trying the circuit’s performance is essential. The modern circuit simulators are robust and accurate and don’t stand in for a physical product. The changes in schematic and other design documents happen in the layout stage. The ECAD designers use the physical placement of copper features and components to perfect the design intent. Product development teams will need a layout designer or capable engineer who needs to work with a third party to finish the step.

Engineering services

PCB layout is not only engineering survival where some customers may need PCB as are parts of more extensive systems. Mechanical design, documentation creation, or schematic capture are essential to electronic system elements. With an added benefit, a CM can know the design of the complementary pieces of the electronic system. It will have a smooth production and ease of logistics, and a CM is the best position to give the added service necessary to support manufacturing.

A PCB is another commodity bought by assembly houses. However, the PCB is necessary for optimal performance of any electronic device. The items are some suggestions you would like to consider while selecting. You must not compromise quality and choose and do your work. You will realize that looking for the proper PCB manufacturer is essential for an effective electronic device.